|

HYDROGEN

Please use our A-Z INDEX to navigate this site where page links may lead to other sites or see HOME

|

|

|

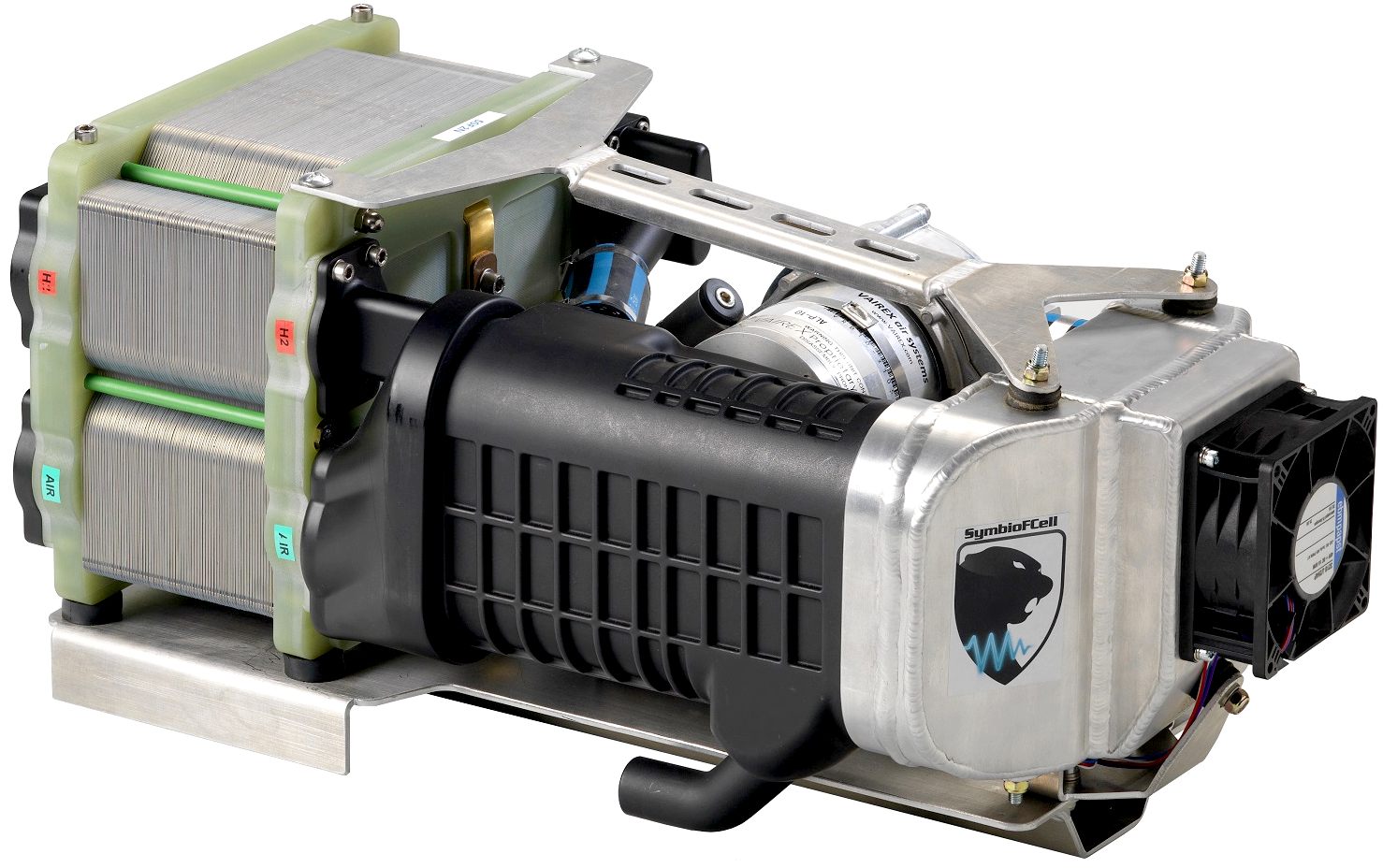

Hydrogen power is the next stage of sustainable development for electrics, by extending range significantly for passenger vehicles and making the practical operation of long range heavy goods vehicles possible. But what about when a fuel cell breaks down? Roadside recovery will take you to the nearest garage for a conventional FCEV, but with the SmartNet™ Universal system, you can have a replacement fitted in a couple of minutes and be back on your way.

Hydrogen is gathering support as a potential replacement for fossil-based fuels such as petroleum, diesel, coal, oil, and natural gas - that are subsidised. But there is as yet little in the way of an infrastructure - which may be seen as a good thing - to be able re-think ways of accommodating both hydrogen and battery vehicles during what is soon to become an intense transitional phase as we close in on 2030, and before too much is invested by competing parties (Lithium Vs HFC), rather than looking to cooperate with one another.

Battery and HFC OEMs working alongside each other to provide a solution to infrastructure insecurity makes a lot of sense.

Inevitably in the early years such infrastructure will grow slowly as the demand for fuel cell vehicles rises. During the introduction phase (i.e until 2030), the number of stations will remain low (In 2019 Europe had 177 hydrogen stations at the end of the year, 87 of which are in Germany. France is second in Europe with 26 operating stations. The UK has around 14 in 2021) but will increase faster than the demand for hydrogen to ensure an adequate hydrogen refuelling network coverage allowing FCEV sales to a broader market.

Putting that into perspective, there are no ammonia or methanol service stations.

This requires a deployment of 100’s of stations per country, at least 200 in the US. But that is a gross underestimate if we are to equal the convenience of fossil-fuel stations.

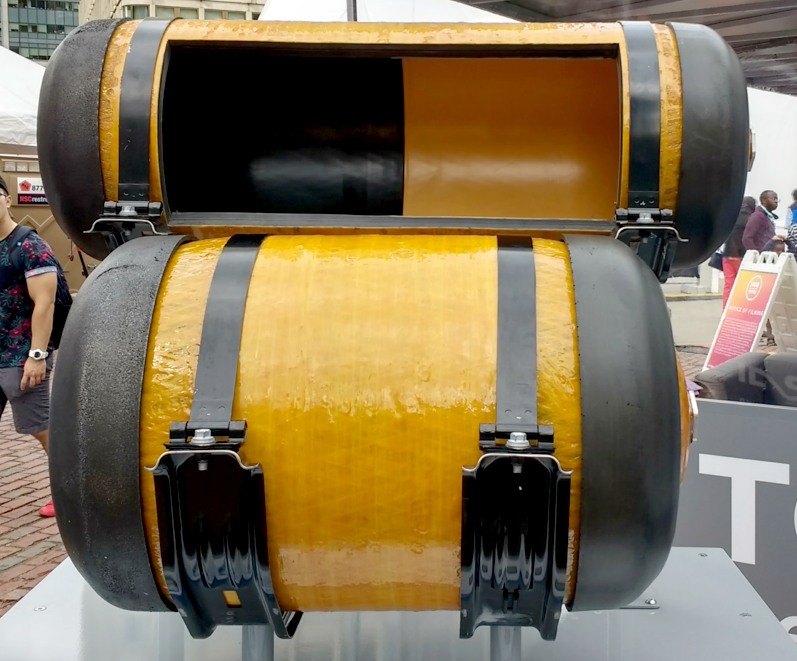

Tank pressures have been globally standardised @ 700-bar, or 10,000 pounds per square inch (psi). These are the cylinders from a Toyota Mirai.

Service stations investment costs will remain relatively high in the early years and with equivalent low utilization, station investors require support to justify the challenging in advance investments in the stations before vehicles arrive in large numbers. Profitability of such stations may only take place as electric vehicle sales increase, being seen as a long term investment. With SmartNet™, the financial risk is much reduced, with charging of battery EVs being possible using green hydrogen, as energy sales, to overcome the potential losses of operating a FCEV only station.

The storage potential of hydrogen is particularly beneficial for power grids, as hydrogen allows for renewable energy to be kept not only in large quantities, but also for long periods. This means that hydrogen can help improve the flexibility of energy systems by balancing out supply and demand when there’s either too much or not enough power being generated. This will also help boost energy efficiency in every country in the world, with Japan taking a lead in such technology and Europe following hot on their heels. Though it is California in the US that has the most H2 refuelling stations, to cater for their wealthier clean air enthusiasts.

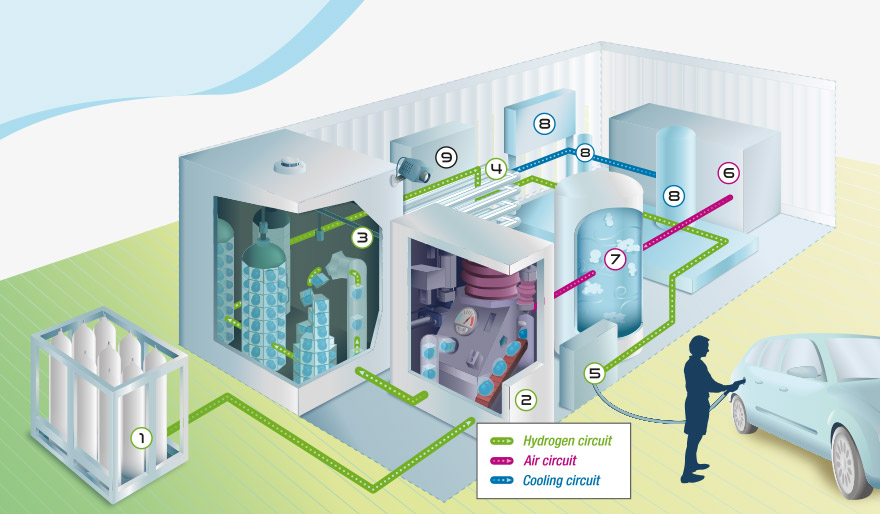

A proposed Hydrogen Refuelling Station by Air Liquide, where hydrogen is made from water on site, compressed and stored in cylinders before being dispensed to FECV customers. These HRS's can only service hydrogen powered vehicles - and there is no load levelling ability. For that you'd need our Universal Smart Batteries.

In

theory, and for most applications, hydrogen is an attractive option: a

relatively plentiful, renewable substance

whose use causes only a small environmental disturbance compared to, for

instance, airborne emissions of carbon

dioxide or particulate materials (PM2.5 and PM10).

Unlike fossil

fuels, hydrogen needs to be processed out of something else

and delivered to the point of use.

Typically, hydrogen is delivered to a fuelling location in the same way as it is distributed to industry: in pressurised tanks on lorries. However, at suitable sites hydrogen can be produced on-site by electrolysis, in the best case with the aid of renewable electricity obtained via direct coupling (wind/solar), or through grid-balancing services.

With the increasing possibility of there being more hydrogen cars, there is the need for methods to store hydrogen that are both lightweight and safe.

Compressed

hydrogen can be stored on board in tanks based on type IV carbon-composite

technology, an all-composite construction featuring a polymer, liner

(typically a high-density polyethylene (HDPE)) with carbon fibre or hybrid

carbon/glass fibre composite. The composite materials carry all of the

structural loads. The pressures used are usually either 350 bar or 700 bar

(5-10,000 psi).

Hydrogen is also stored in cryogenic conditions in insulated tanks

(typically cooled to -253°C and at pressures of between 6 and 350 bar), or

using advanced materials, (ie within the structure or on the surface of

certain materials). Equally, such methods lend themselves to incorporation

in cartridges of the same physical dimensions as pressurized tanks, or, for

that matter, battery

packs.

USA - In 2003, US President George Bush announced a program called the Hydrogen Fuel Initiative (HFI) during his State of the Union Address. This initiative was supported by legislation in the Energy Policy Act of 2005 (EPACT 2005) and the Advanced Energy Initiative of 2006, aimed to develop hydrogen, fuel cell and infrastructure technologies to make fuel-cell vehicles practical and cost-effective by 2020.

Obviously, the legislation did not work, or we'd seen hydrogen cars selling like hot cakes. Whereas, there are significant sales of battery electric cars.

CONVERSION CHAIN NEGATIVES

Going against hydrogen, is the losses in efficiency during the conversion process, where water is electrolyzed, the gas is then compressed and converted via a fuel cell to electricity. The conversion chain only yields around 25% as opposed to battery powered electrics, where the conversion chain is around 70%. These figures are constantly changing, mainly due to the improvement in electrolysis technology. But PEM fuel cells are only around 50% efficient, in converting hydrogen to electricity. Hence, the only real advantage is long term sustainability, that battery technology alone may not be able to provide.

We should therefore, use all the means at our disposal to improve EVs, by way of range extending technology. This includes solar assistance, something that is hardly ever considered.

ELEMENTAL

Hydrogen (H), a colourless, odourless, tasteless, flammable gaseous substance that is the simplest member of the family of chemical elements. The hydrogen atom has a nucleus consisting of a proton bearing one unit of positive electrical charge; an electron, bearing one unit of negative electrical charge, is also associated with this nucleus. Under ordinary conditions, hydrogen gas is a loose aggregation of hydrogen molecules, each consisting of a pair of atoms, a diatomic molecule, H2. The earliest known important chemical property of hydrogen is that it burns with oxygen to form water, H2O; indeed, the name hydrogen is derived from Greek words meaning “maker of water.”

Hydrogen is the most abundant element in the universe (three times as abundant as helium, the next most widely occurring element), but makes up only about 0.14 percent of Earth’s crust by weight. It occurs, in vast quantities as part of the water in oceans, ice packs, rivers, lakes, and the atmosphere. As part of innumerable carbon compounds, hydrogen is present in all animal and vegetable tissue and in petroleum. Though it is said that there are more known compounds of carbon than of any other element, since hydrogen is contained in almost all carbon compounds and also forms a multitude of compounds with all other elements (except some of the noble gases), it is possible that hydrogen compounds are more numerous.

LINKS & REFERENCE

https://ec.europa.eu/energy/topics/energy-system-integration/hydrogen_en

Hydrogen powered vehicles are becoming more popular, especially buses in cities, where diesel particulates are choking the population and causing cancer. There is an abundance of clean wind and solar energy that can produce green hydrogen, something that at the moment is not happening.

Please use our A-Z INDEX to navigate this site or see HOME

This website is provided on a free basis to promote zero emission transport in Europe and Internationally. Copyright © Climate Change Trust & Universal Smart Batteries 2022. Solar Studios, BN271RF, United Kingdom.

|